Leave Your Message

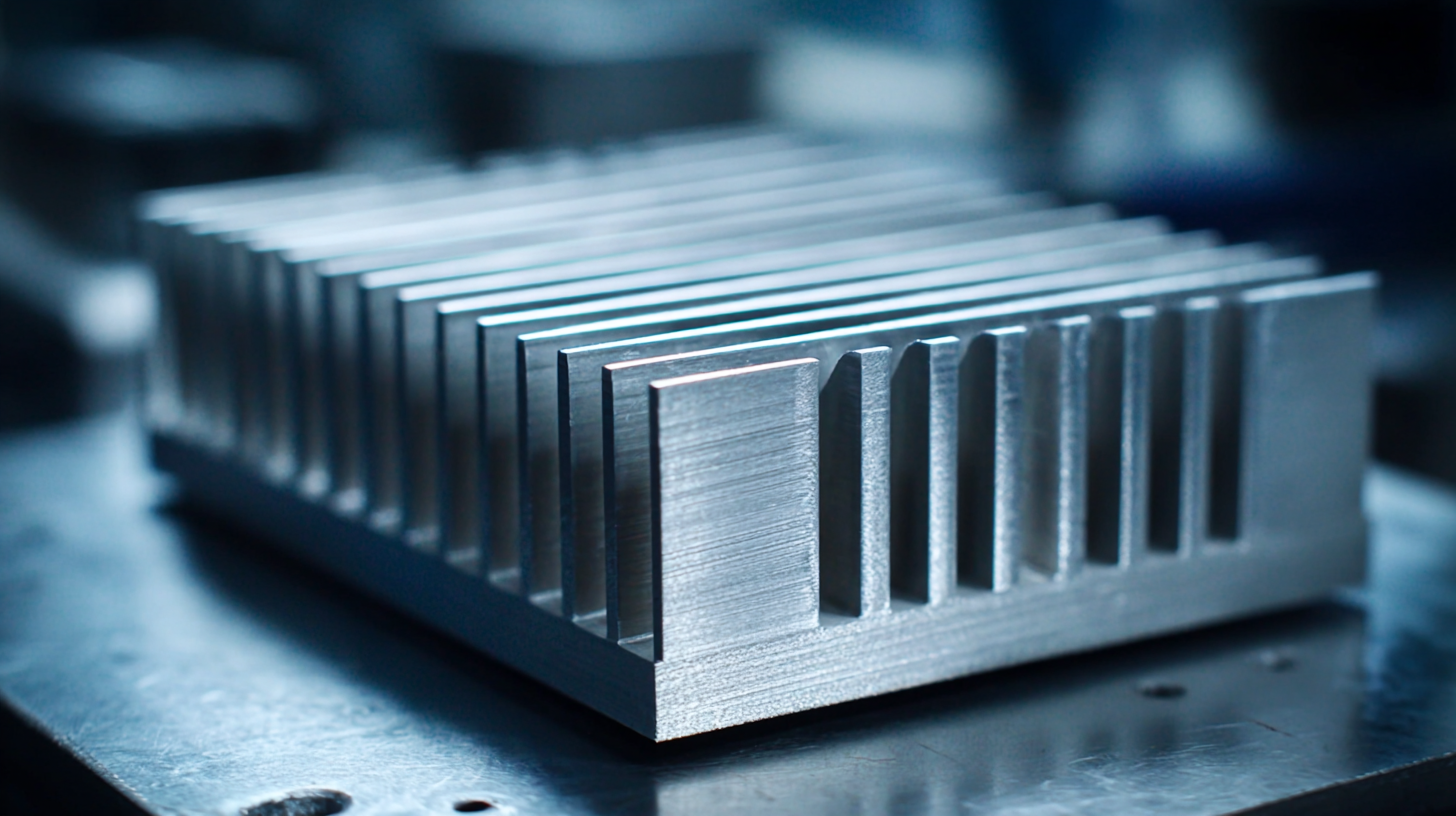

In today's fast-paced technological landscape, efficient thermal management is paramount for the performance and longevity of electronic devices. The advent of aluminum heat sinks has revolutionized this domain, offering a lightweight and highly effective solution for dissipating heat generated by increasingly compact and powerful electronic components. These aluminum heat sinks not only enhance thermal conductivity but also provide exceptional durability and corrosion resistance, making them an ideal choice for various applications, from consumer electronics to industrial machinery. As the demand for more efficient cooling solutions grows, understanding the unique advantages of aluminum heat sinks becomes essential. This article delves into how these innovative thermal management tools are unlocking new levels of efficiency, paving the way for advancements in electronic design and performance.

In modern electronics design, managing heat is critical for ensuring device longevity and optimal performance. Aluminum heat sinks have emerged as a vital component in this thermal management strategy. Their lightweight construction and excellent thermal conductivity make them ideal for dissipating heat away from crucial components, such as CPUs and GPUs. As electronic devices become more compact and powerful, the efficiency of heat dissipation becomes paramount, and aluminum heat sinks provide an effective solution.

The integration of aluminum heat sinks into electronic designs signifies a shift towards more reliable and efficient systems. They can be customized to fit various configurations and designs, enabling engineers to optimize their thermal management solutions without compromising on space or aesthetics. Moreover, the cost-effectiveness and recyclability of aluminum make it an attractive choice for manufacturers aiming to balance performance with sustainability. As a result, aluminum heat sinks are not just functional components; they play a crucial role in innovating thermal management in the rapidly evolving landscape of electronics.

| Parameter | Value | Importance |

|---|---|---|

| Material | Aluminum | Optimal thermal conductivity |

| Thermal Conductivity | 205 W/mK | Enhances heat dissipation |

| Weight | Low (varies by design) | Reduces overall device weight |

| Cost | Moderate | Cost-effective for mass production |

| Design Flexibility | High | Allows customized shapes and sizes |

| Corrosion Resistance | Good (with proper treatment) | Increases lifespan of components |

| Temperature Range | -40°C to 150°C | Adapts to various applications |

Aluminum has emerged as the material of choice for thermal management in electronics, offering several key advantages over alternatives like copper or plastic. One of its most significant strengths lies in its lightweight nature, which reduces overall device weight without compromising performance. This is particularly beneficial in portable electronics where weight is a critical factor. Additionally, aluminum's excellent thermal conductivity ensures that heat is dissipated efficiently, preventing overheating and extending the lifespan of electronic components.

Another major advantage of aluminum is its corrosion resistance. Unlike copper, which can oxidize and tarnish, aluminum maintains its integrity even in harsher environments, making it suitable for diverse applications. Its ability to be extruded into complex shapes allows for innovative designs in heat sinks, maximizing surface area for better airflow and cooling efficiency. Moreover, aluminum's cost-effectiveness, coupled with its recyclability, positions it as a sustainable choice in the ever-evolving electronics landscape, reinforcing its role in enhancing both performance and environmental responsibility.

Innovative designs in aluminum heat sinks are transforming thermal management in electronics, crucial for maintaining optimal performance as electronic components become increasingly powerful. Recent advancements include selective-orienting short fiber composites that enhance heat dissipation through tailored local fiber orientations. Such innovations can significantly elevate the thermal performance of heat sinks, ensuring efficient heat removal in compact electronic devices.

Additionally, novel fin designs, such as disk and helical fins, have been shown to improve thermohydrodynamic properties, further optimizing heat dissipation mechanisms. The integration of these advanced designs allows for better airflow and heat transfer, essential for maintaining the reliability and efficiency of high-performance electronics. Moreover, techniques like chemical roughening present a cost-effective approach to enhance the surface area of aluminum heat sinks, demonstrating that innovative approaches can lead to significant improvements in thermal management solutions.

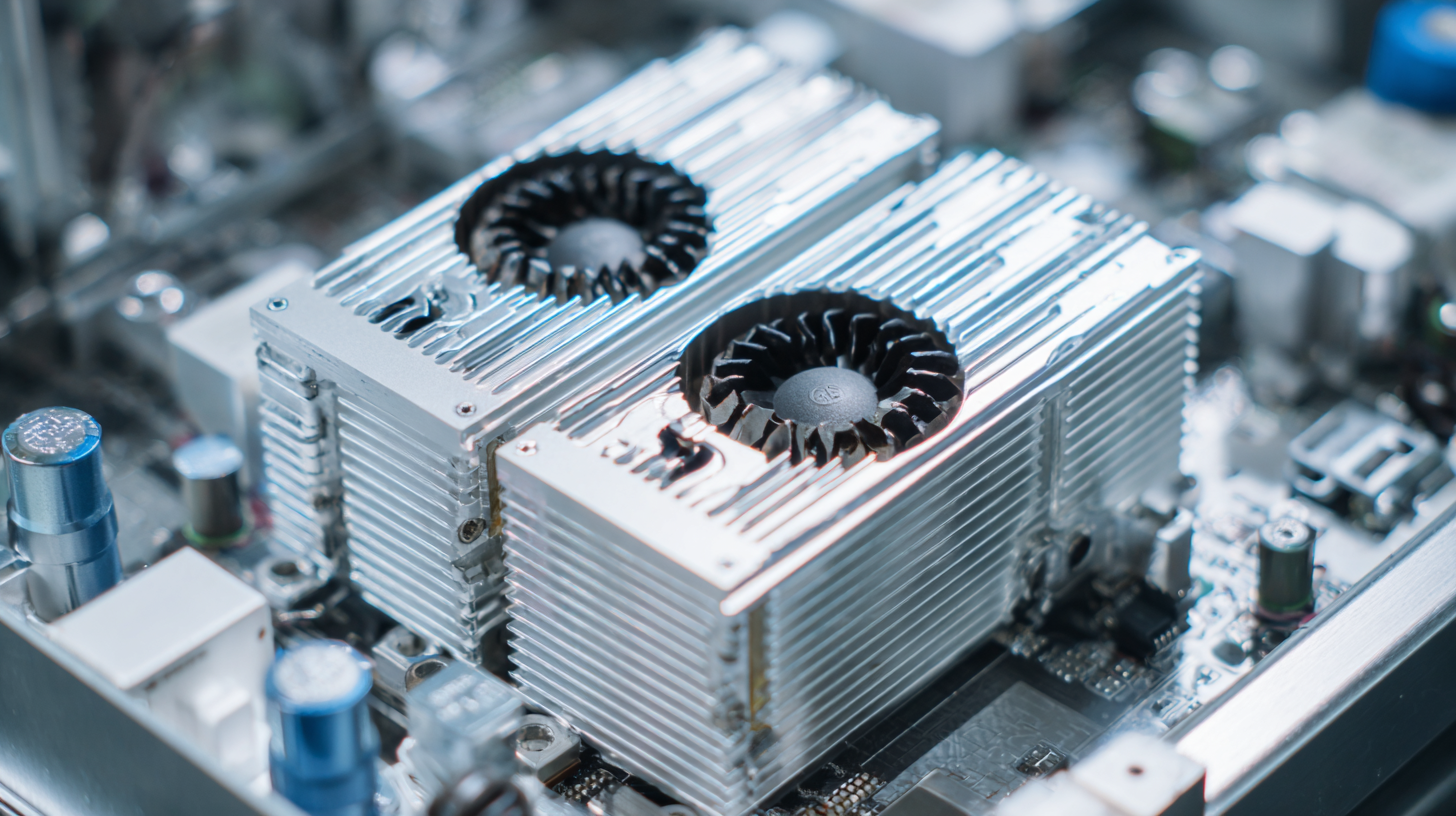

Aluminum heat sinks have become essential in the realm of thermal management for high-performance electronic devices, offering unparalleled efficiency and versatility. Their lightweight nature and excellent thermal conductivity make them ideal for dissipating heat generated by components like CPUs, GPUs, and power transistors. In applications ranging from consumer electronics to industrial machinery, aluminum heat sinks ensure optimal operating temperatures, enhancing the longevity and reliability of devices.

In high-performance computing and gaming, for instance, aluminum heat sinks are integral in maintaining performance benchmarks. The ability to effectively regulate temperature allows processors to operate at their full potential, preventing thermal throttling that can degrade performance. Furthermore, in the realm of telecommunications and renewable energy systems, these heat sinks play a pivotal role in managing heat generated in power amplifiers and solar inverters, helping to maximize efficiency and energy output. As electronic devices continue to push the boundaries of performance, aluminum heat sinks will remain a key technology in advancing thermal management solutions.

The advancement of aluminum heat sink technology has significantly transformed thermal management in the electronics sector. As devices continue to shrink in size while increasing in performance, the demand for efficient heat dissipation has led to innovative designs and materials. One of the most notable trends is the development of enhanced heat sink geometries that maximize surface area without increasing weight. These new designs not only improve thermal conductivity but also allow for better airflow, contributing to more efficient cooling solutions.

The advancement of aluminum heat sink technology has significantly transformed thermal management in the electronics sector. As devices continue to shrink in size while increasing in performance, the demand for efficient heat dissipation has led to innovative designs and materials. One of the most notable trends is the development of enhanced heat sink geometries that maximize surface area without increasing weight. These new designs not only improve thermal conductivity but also allow for better airflow, contributing to more efficient cooling solutions.

Moreover, the integration of advanced manufacturing techniques, such as additive manufacturing and CNC machining, has facilitated the creation of customized heat sinks tailored to specific applications. This flexibility enables engineers to optimize performance for various electronic components, ensuring that higher power densities can be managed effectively. Additionally, the trend towards sustainability has prompted the exploration of eco-friendly aluminum alloys that offer improved performance while minimizing environmental impact. As these advancements continue to evolve, aluminum heat sinks are set to play a crucial role in driving the efficiency of next-generation electronic devices.