Leave Your Message

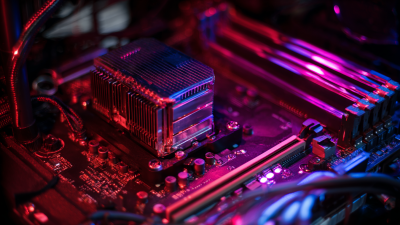

When it comes to ensuring the optimal performance and longevity of electronic components, effective thermal management is crucial. One of the most significant factors in achieving this is the selection of the right heat sink. Pcm Heat Sink solutions stand out in the realm of electronics cooling due to their ability to dissipate heat efficiently and maintain safe operating temperatures. However, with a variety of options available, choosing the appropriate Pcm Heat Sink can be a daunting task for engineers and hobbyists alike.

In this guide, we will explore the essential considerations that should influence your decision-making process when selecting a Pcm Heat Sink for your applications. From understanding the thermal interface materials to assessing the specific thermal requirements of your electronics, we will provide insights into the top digital types available in the market today. By the end of this discussion, you will be equipped with the knowledge needed to make informed choices that enhance the performance and reliability of your electronic systems.

Phase Change Material (PCM) heat sinks are innovative thermal management solutions that play a crucial role in electronic cooling. These specialized heat sinks are designed to absorb, store, and release heat through phase change processes, which can significantly improve the efficiency of cooling systems. At their core, PCM heat sinks utilize materials that transition between solid and liquid states at specific temperatures, making them ideal for applications where temperature control is critical.

The working principle of PCM heat sinks is straightforward yet effective. When an electronic component generates heat, the PCM within the heat sink absorbs this excess energy, causing it to melt and store thermal energy as latent heat. Once the component cools down, the PCM solidifies, releasing the stored heat gradually. This capability allows for a more uniform temperature distribution across the component, preventing overheating and ensuring optimal performance. By incorporating PCM technology, engineers can enhance the lifespan of electronic devices while maintaining reliability under demanding conditions.

When choosing the right PCM heat sink for your electronics, several factors must be taken into account to ensure optimal cooling performance. One of the primary considerations is the thermal conductivity of the PCM material. High thermal conductivity materials facilitate better heat transfer, allowing the heat sink to absorb and dissipate heat more efficiently. Therefore, evaluating the specific thermal properties of the PCM is crucial in matching it with your electronics’ thermal requirements.

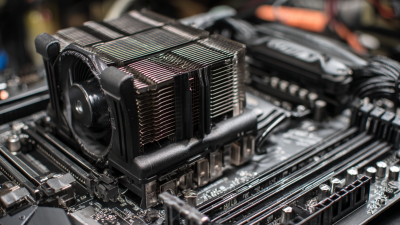

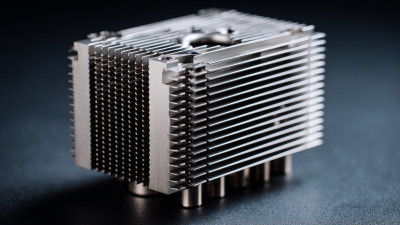

Another important aspect to consider is the design and size of the heat sink. The surface area plays a significant role in heat dissipation; a larger surface area allows for more heat to escape into the surroundings. Additionally, the geometry of the heat sink can affect airflow and thermal performance. Compatibility with existing components is also vital, as the heat sink must fit within spatial constraints without obstructing other parts. By taking these factors into account, you can ensure that the chosen PCM heat sink meets the cooling needs of your electronics effectively.

This chart illustrates the various factors influencing the selection of PCM heat sinks, along with their respective importance ratings.

When selecting the ideal PCM (Phase Change Material) heat sink for your electronics cooling needs, it's essential to explore the top models set to make waves in 2025. Among the frontrunners is the Model X, which boasts an impressive thermal storage capacity and an innovative lightweight design. Designed for high-performance applications, its integrated thermal sensors ensure efficient temperature regulation, providing peace of mind for engineers and designers alike.

Another standout is the Model Y, renowned for its superior thermal conductivity and durability. This heat sink incorporates advanced composite materials that effectively dissipate heat while maintaining a compact footprint. Moreover, its versatility allows for seamless integration into various electronic devices, making it an excellent choice for everything from consumer electronics to industrial applications. The benefits of choosing a high-quality PCM heat sink extend beyond mere cooling; they enhance overall system stability and reliability, making them a wise investment for 2025 and beyond.

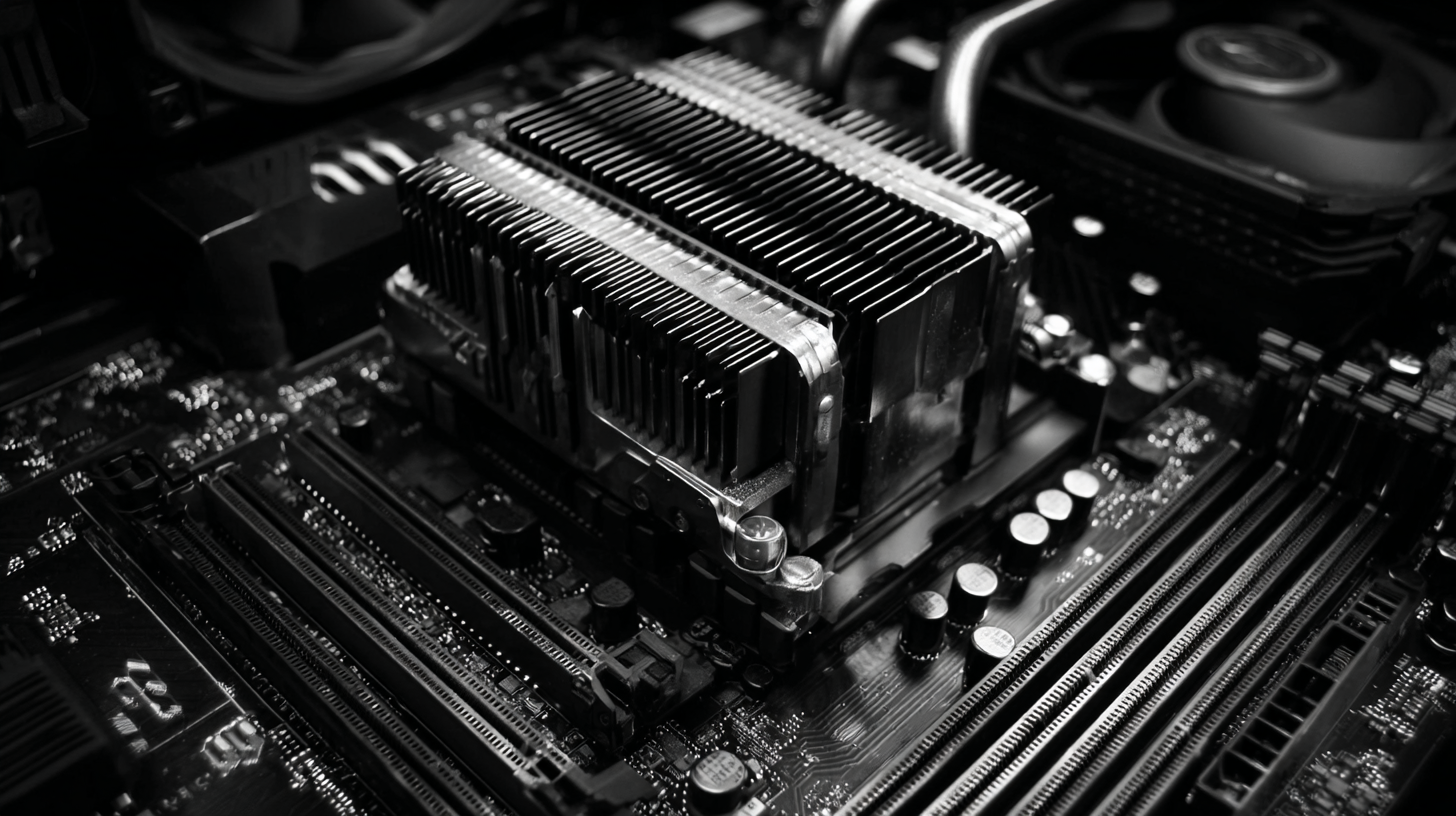

When evaluating cooling solutions for electronic systems, understanding the differences between Phase Change Material (PCM) heat sinks and traditional heat sinks is crucial. PCM heat sinks leverage the unique thermal properties of materials that absorb and release significant amounts of latent heat during phase transitions. This characteristic allows them to maintain more stable operating temperatures compared to traditional metal heat sinks, which primarily rely on conduction to dissipate heat. As a result, PCM solutions can be smaller and lighter while effectively managing higher thermal loads.

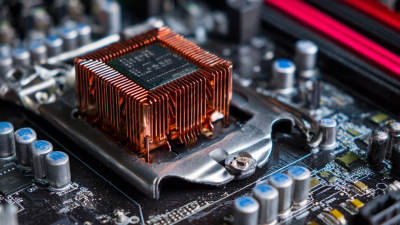

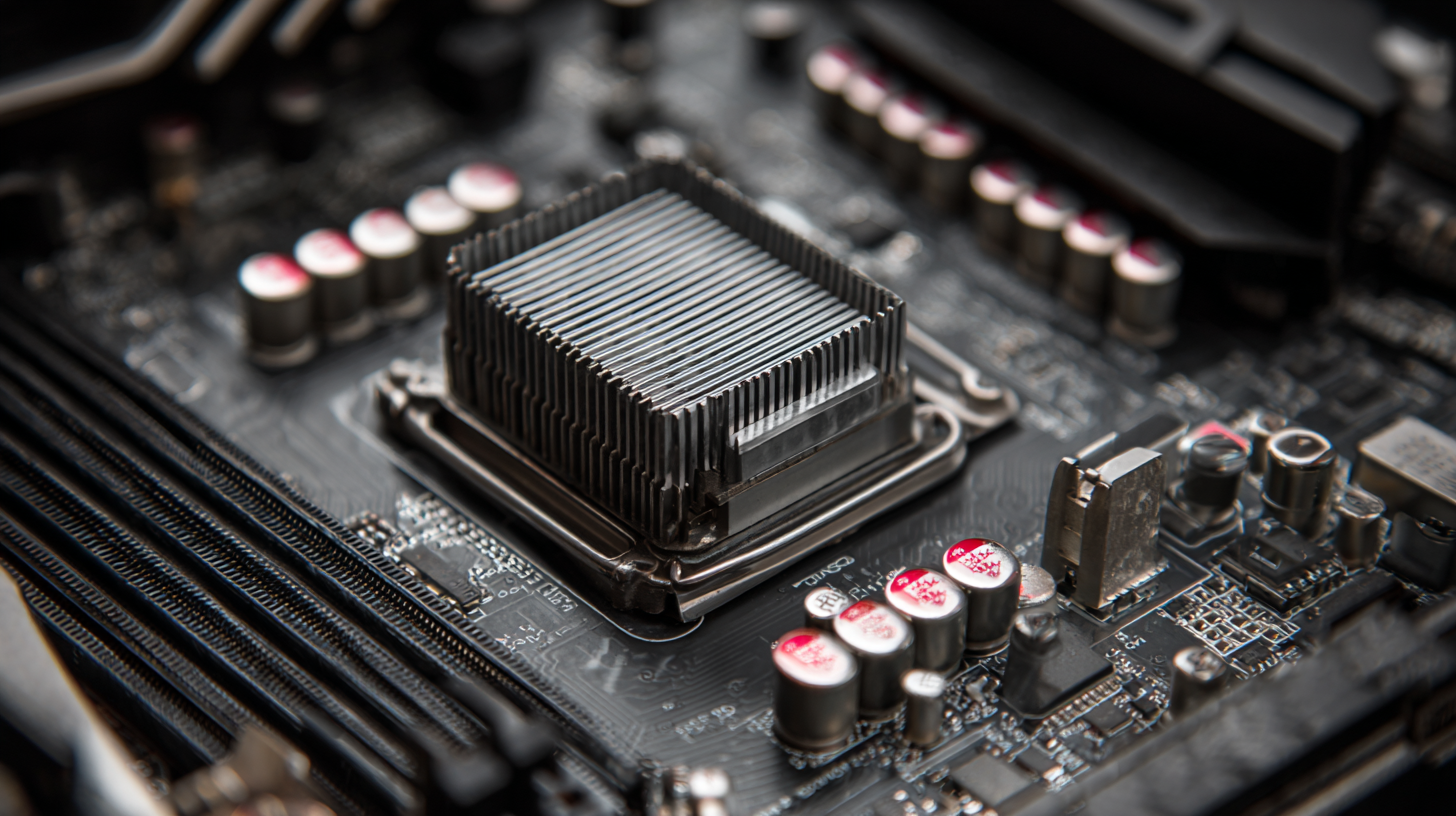

In contrast, traditional heat sinks often involve greater mass and surface area to achieve efficient heat dissipation, leading to bulkier designs. They are typically made from materials like aluminum or copper, which can efficiently conduct heat away from the source, but may struggle with heat accumulation in high-load scenarios. While traditional heat sinks can be reliable and cost-effective, PCM solutions offer an innovative alternative that can enhance thermal performance, especially in compact and high-density electronics. Thus, the choice between PCM and traditional heat sinks should be based on specific application requirements and thermal management goals.

When it comes to ensuring optimal performance of PCM heat sinks, installation and maintenance are critical components that cannot be overlooked. Proper installation plays a vital role in maximizing the heat sink’s efficiency. It is essential to ensure that the heat sink is firmly attached to the electronic component it is cooling, with minimal thermal interface material thickness to enhance thermal conductivity. Aligning the heat sink to allow for natural airflow can further improve passive cooling performance, as studies have shown that varying heat sink designs significantly affect heat dissipation.

Maintenance is equally important for sustaining the heat sink's functionality over time. Regular cleaning of the heat sink surface to remove dust and debris can prevent thermal resistance from accumulating, which would otherwise hinder heat transfer. Additionally, periodic checks on the integrity of the PCM inside the heat sink can determine if there are any phase change material leaks or degradation. Keeping the heat sink in optimal condition not only extends its lifespan but also ensures that your electronic components remain cool and function effectively, avoiding thermal runaway scenarios and enhancing overall reliability.

| Parameter | Description | Importance | Recommended Value |

|---|---|---|---|

| Thermal Conductivity | Ability of the heat sink material to conduct heat away from the component. | High | > 200 W/mK |

| Surface Area | The total area of the heat sink that is exposed to air, aiding heat dissipation. | High | Maximize for your design |

| Weight | The mass of the heat sink that can affect its installation and mounting. | Medium | < 500 grams |

| Mounting Type | Method of attaching the heat sink to the electronic component. | High | Screw or Clip Mount |

| Fin Design | Shape and arrangement of the fins on the heat sink. | Medium | Straight or Unidirectional |

| Airflow Compatibility | How well the heat sink is designed to work with airflow from fans or natural convection. | High | Designed for high airflow |