Leave Your Message

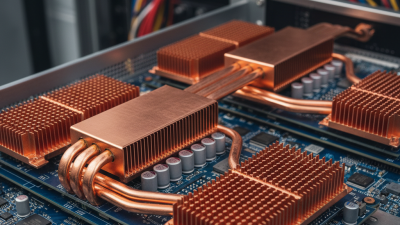

In the quest for efficient thermal management, selecting the right Copper Heat Sink is crucial. Industry studies indicate that copper heat sinks can enhance thermal performance by up to 30% compared to aluminum options. This significant advantage stems from copper's superior thermal conductivity, allowing for better heat dissipation in critical applications.

However, choosing the right Copper Heat Sink is not always straightforward. Factors such as thermal resistance, design, and size play vital roles in performance. Many projects overlook these details, leading to inefficient heat transfer and potential system failures. Reports suggest that poor heat sink selection can reduce component lifespan by over 20%.

Reflecting on this, designers must balance cost, performance, and material properties. While copper excels in heat conduction, its weight and cost can be obstacles. This creates a challenge for engineers to optimize designs without compromising project integrity. Understanding these complexities is key for anyone looking to implement Copper Heat Sinks effectively.

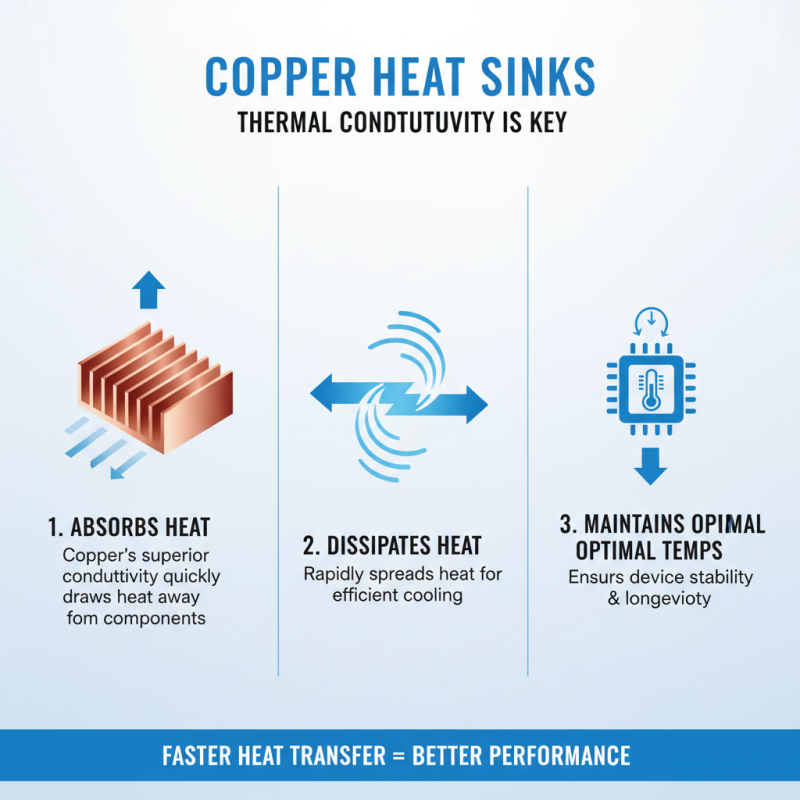

When selecting a copper heat sink, thermal conductivity is key. Copper is known for its excellent ability to absorb and dissipate heat. This property is crucial for maintaining safe operating temperatures in electronic devices. A heat sink that efficiently transfers heat keeps components running smoothly.

Not every copper heat sink is created equal. Factors such as shape, size, and surface area impact performance. A larger surface area can enhance heat dissipation but may also lead to space constraints in a design. Users often rush through this choice, risking less efficient cooling solutions.

Understanding the thermal conductivity rating is essential. Higher ratings indicate better performance, but real-world applications can vary. Poor thermal interface materials can undermine even the best heat sinks. It's vital to evaluate the entire system, not just the heat sink itself. Each project presents unique challenges and solutions.

When selecting a copper heat sink, there are key factors to consider. Thermal conductivity is paramount. Copper boasts a thermal conductivity of about 400 W/mK, significantly higher than aluminum. This property allows for efficient heat dissipation. For applications requiring rapid cooling, choose a heat sink with a larger surface area.

Another critical factor is the design. Fin designs, for example, greatly influence airflow and cooling efficiency. A study indicates that proper fin spacing can enhance performance by up to 35%. The shape and thickness of the heat sink matter. Thicker sinks can hold more heat but may increase weight.

Finally, consider your project’s space constraints. Not all designs fit well, especially in compact environments. Review thermal performance data for your specific needs. Each installation may reveal the copper heat sink's strengths and weaknesses. Balancing these elements can lead to improved thermal management in your projects.

This chart illustrates key factors to be considered when selecting a copper heat sink for your project. The data includes thermal conductivity, cost, density, thickness, and surface area, which are critical in evaluating the efficiency and suitability of a heat sink for specific applications.

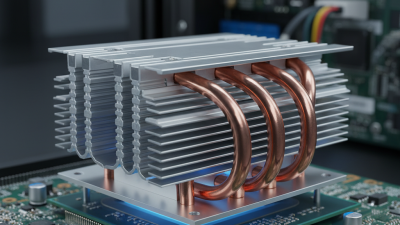

When choosing a copper heat sink, size and shape significantly influence heat dissipation efficiency. The primary goal is to maximize surface area while maintaining a compact design. Studies show that heat sinks with a larger surface area are more effective in transferring heat. A report from the Thermal Management Association noted that increasing the surface area by just 20% can improve thermal performance by nearly 15%.

Shape also plays a crucial role. The most common configurations include flat, pin fin, and extruded designs. Each has its unique benefits and limitations. For instance, flat heat sinks provide ease of installation but may not dissipate heat as quickly as pin fin designs. Pin fin heat sinks, on the other hand, can enhance airflow and heat transfer but may require more space. The choice often relates to the specific application and available space.

Sometimes, achieving optimal performance feels elusive. You may choose a design that looks good but doesn't perform well in real-world conditions. It's essential to test different sizes and shapes to find the best fit for your project. Consider the thermal simulations available. They can provide insights but might not always predict practical outcomes accurately.

| Dimension | Value | Heat Dissipation Efficiency |

|---|---|---|

| Length (mm) | 100 | 85% |

| Width (mm) | 80 | 80% |

| Height (mm) | 40 | 75% |

| Fin Thickness (mm) | 2 | 78% |

| Surface Treatment | Anodized | 90% |

| Weight (g) | 150 | N/A |

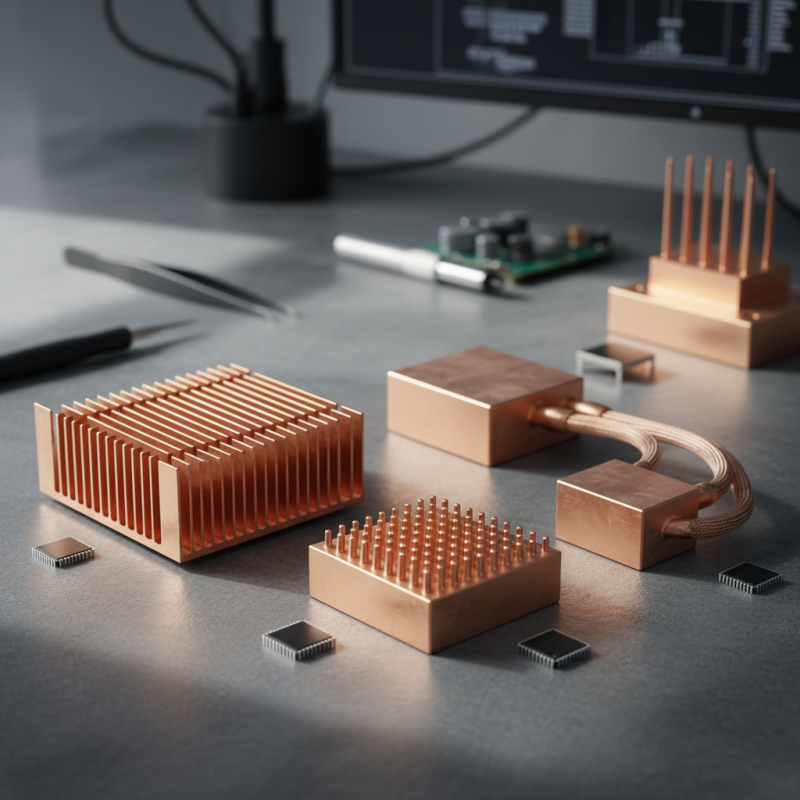

Choosing the right heat sink can greatly impact project efficiency. Copper heat sinks are often favored due to their superior thermal conductivity, boasting around 400 W/m·K compared to aluminum's 235 W/m·K. This difference is significant when considering heat dissipation requirements. For projects demanding high performance, copper's efficiency may justify its higher cost.

However, cost-effectiveness must be examined. Copper's price is about four times that of aluminum. Some projects may not need the advanced thermal properties that copper offers. For example, in applications with lower heat loads, aluminum may suffice. A detailed cost analysis can help determine the best material for your specific application.

Tips: Consider the life cycle of materials. While copper has a higher initial cost, its longevity can offset the expense. Evaluate total project costs, not just upfront spending. Also, be mindful of weight. Copper might add unnecessary heaviness to certain designs.

Ultimately, finding the right balance between performance and cost is crucial. Adjustments such as optimizing the heat sink design or exploring alternative alloys might lead to better outcomes. It’s important to rethink assumptions about material suitability for your project. Keep testing and analyzing your choice.

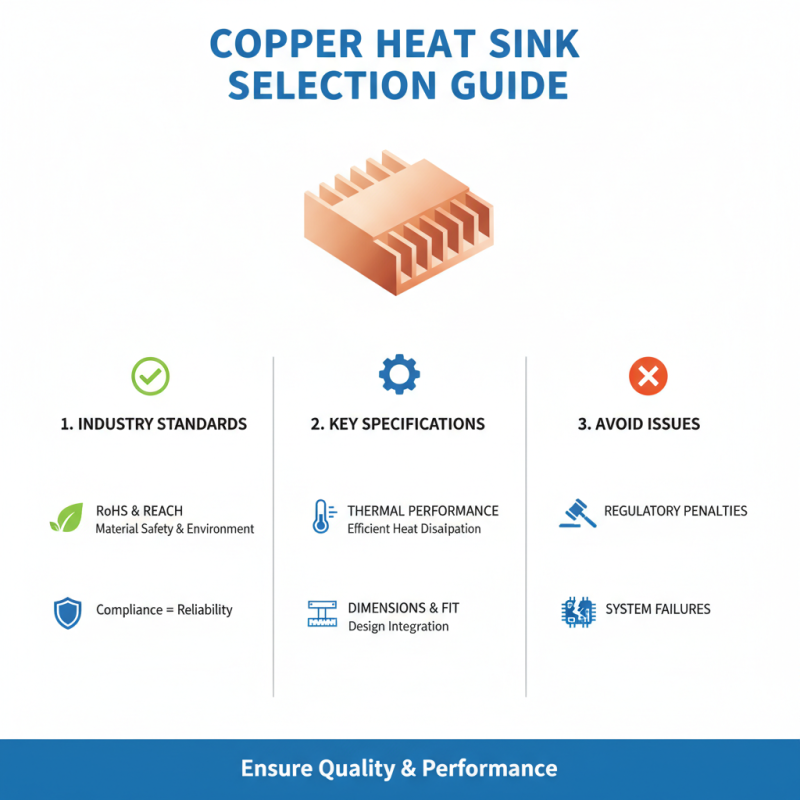

When selecting a copper heat sink, compliance with industry standards is crucial. Different applications may require various specifications. Standards like RoHS and REACH guide material safety and environmental impact. Not adhering to these can lead to failures or regulatory issues. Consider thermal performance and dimensions to ensure your heat sink fits your design needs.

Tips: Verify compliance documents. This ensures that the materials meet safety regulations. Familiarize yourself with relevant certifications for your application. It can save you time and trouble later.

Evaluating the heat sink’s effectiveness involves analyzing its surface area and design. A well-designed heat sink maximizes airflow and cooling. Pay attention to the thermal conductivity of copper. However, not all copper heat sinks are created equal. Some may not perform as expected. Read reviews and seek connections in your industry for feedback and recommendations.

Tips: Test prototypes in actual conditions. This helps identify potential issues before full-scale production. Don’t rely solely on numbers in catalogs. Real-world performance can differ significantly.