Leave Your Message

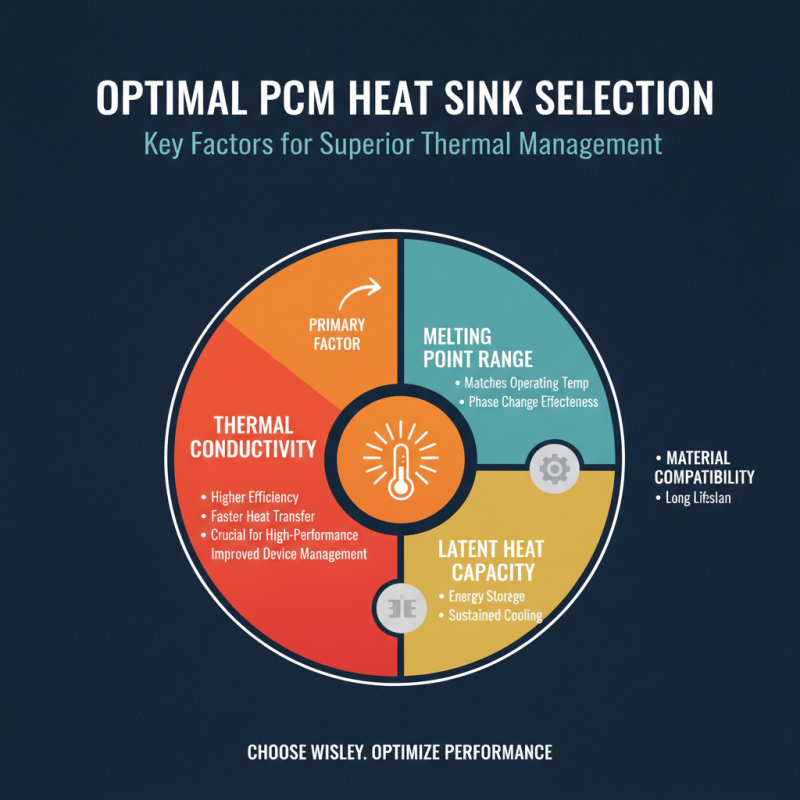

Choosing the right PCM heat sink is crucial for thermal management. It affects both efficiency and device longevity. Various factors contribute to the selection process, impacting performance under different conditions.

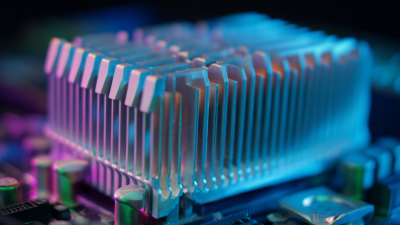

Many users overlook thermal conductivity or the physical design of the PCM heat sink. Each component has its own heat dissipation needs. Understanding your specific application can lead to better choices. There are different shapes and materials available, which serve unique purposes.

Often, users face challenges in balancing cost with performance. A cheaper option may save money now but could lead to failures later. It's essential to reflect on these factors and make informed decisions. Selecting the best PCM heat sink means considering long-term benefits, not just immediate costs.

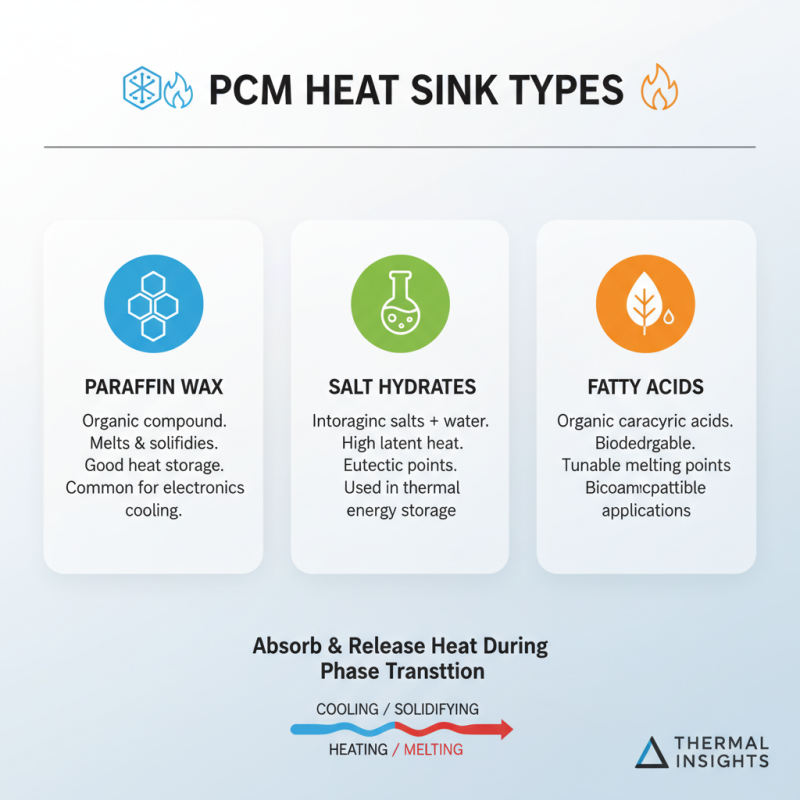

Phase Change Materials (PCM) heat sinks are innovative solutions for effective cooling. They absorb and release thermal energy during phase transitions. The materials change state, usually from solid to liquid, to handle excess heat. This process helps maintain a stable temperature in various applications.

Choosing the right PCM heat sink involves understanding your cooling needs. Consider the temperature range and environment. Some materials are better suited for high temperatures, while others excel at lower levels. Awareness of heat generated by your device is crucial. You might find your choice requires more testing and adjustments than expected. Fire up those prototypes, and evaluate how they perform under real conditions.

Efficiency is key, but cost is important too. Budget constraints can limit your options. Experimenting with various PCM types can lead to unexpected outcomes. Sometimes, the most popular choices aren’t the best for your situation. It’s essential to remain flexible and open to new ideas during your selection process. Embrace the challenge of finding the right balance.

When selecting a PCM heat sink, several key factors come into play. First, consider the thermal conductivity of the material. Materials with higher thermal conductivity can transfer heat more efficiently. This is particularly vital in high-performance applications. A well-conducting heat sink can drastically improve the thermal management of your device.

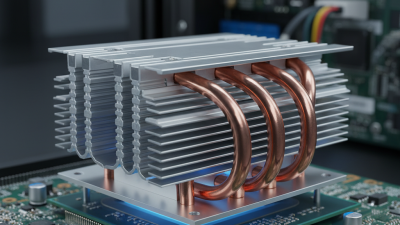

Next, analyze the size and shape of the heat sink. Ensure it fits within the physical constraints of your project. Inadequate sizing can lead to inefficient cooling. A larger heat sink may offer better performance, but only if it fits your design specifications. Also, consider the airflow around the heat sink. If the air circulation is poor, even the best heat sink will struggle to dissipate heat effectively.

Don’t overlook the importance of weight and mounting options. A heavy heat sink may put stress on your components. Ensure that it is easy to mount without complicating your design. Reflection is key—sometimes, an over-engineered heat sink can complicate the aesthetic of your setup. Ensuring a balance between functionality and design will create a more harmonious final product.

When selecting a phase change material (PCM) heat sink, understanding the types available is essential. PCM heat sinks utilize materials that absorb and release heat during phase transitions. Some common types include paraffin wax, salt hydrates, and fatty acids. Each type has unique thermal properties, influencing efficiency in specific applications.

Paraffin wax is widely used for its high latent heat capacity. It can effectively manage temperature fluctuations. However, it may face challenges with thermal conductivity. Salt hydrates, while offering great thermal performance, can sometimes lead to issues with corrosion. Their reliability depends on ensuring a sealed environment. Fatty acids are another interesting option, but they also present challenges in terms of a narrower temperature range.

Choosing the right PCM heat sink requires a careful balance of these factors. Efficiency is not only about high heat absorption. It's essential to consider heat transfer rates and long-term stability. Evaluating your cooling needs and running simulations can help. Sometimes, a combination of materials might work best. However, it’s crucial to remain aware of potential downsides in each option.

Choosing the right PCM (Phase Change Material) heat sink is crucial for effective cooling. The dimensions of your heat sink directly affect its ability to dissipate heat. Research shows that a poorly sized heat sink can lead to inefficient cooling, resulting in increased temperatures and potential equipment failure. Inadequate sizing often leads to hot spots, which can shorten the lifespan of your components.

When selecting a heat sink, consider the specific application and thermal load. A heat sink that’s too small can struggle to manage heat. Conversely, a heat sink that’s oversized might be unnecessary and costly. According to industry reports, an optimized heat sink can improve thermal performance by up to 20%. This can significantly enhance the efficiency of your cooling system.

Tips: Always measure the available space. Proper fit is essential. Check thermal conductivity values, as these directly impact efficiency. Ensure that your design factor in airflow, as it plays a key role in heat dissipation. Reflecting on design choices is vital. Identify any overlooked factors. Small adjustments can lead to better performance.

| Heat Sink Material | Dimensions (mm) | Weight (g) | Max Heat Dissipation (W) | Recommended Application |

|---|---|---|---|---|

| Aluminum | 100 x 100 x 25 | 150 | 80 | CPU Cooling |

| Copper | 90 x 90 x 20 | 200 | 120 | High-Performance GPUs |

| Graphite | 120 x 120 x 30 | 120 | 90 | LED Lighting |

| Aluminum with PCM | 110 x 110 x 35 | 180 | 150 | Telecom Equipment |

Testing the effectiveness of PCM (Phase Change Material) heat sinks is essential. It ensures they meet your cooling needs. Before diving into the tests, you should understand the key performance metrics. Thermal conductivity and latent heat capacity are crucial. Reports suggest that PCM materials can offer thermal conductivities ranging from 0.2 to 0.6 W/mK.

To evaluate the performance, start with temperature monitoring. Use thermocouples to record surface temperatures during operation. This data helps gauge the heat sink's effectiveness. A study highlighted that using PCM can lower peak temperatures by 20%. However, not all PCM heat sinks perform equally. Some may show less than expected performance under certain conditions. This necessitates reviewing material choices and configurations.

Another area to test is the heat dissipation rate. A controlled environment can simulate real-world scenarios. Record how quickly heat dissipates from the PCM. Some heat sinks might not desorb heat as efficiently as anticipated. An analysis noted a discrepancy of up to 15% in efficiency between different designs. It’s essential to revisit and refine designs based on test outcomes for optimal thermal management.